The 6-Minute Rule for Digital Printing

The 6-Minute Rule for Digital Printing

Blog Article

Excitement About Digital Printing

Table of ContentsThings about Digital PrintingFacts About Digital Printing UncoveredThe Greatest Guide To Digital PrintingA Biased View of Digital PrintingSome Known Details About Digital Printing How Digital Printing can Save You Time, Stress, and Money.Get This Report about Digital PrintingAn Unbiased View of Digital Printing

Modification also enables organizations to attract attention in a jampacked market by creating distinct advertising and marketing products that separate them from their rivals. One of the primary advantages of electronic printing is the ability to publish variable data. Each printed item can be unique, enabling companies to create personalized advertising materials that speak directly to their target audience.Digital printing additionally permits for personalization in the style of marketing materials (Digital Printing). With electronic printing, companies can produce designs that are distinct and tailored to their certain needs.

All about Digital Printing

By printing smaller sized amounts of advertising materials, companies can reduce waste and stay clear of the need for excess stock. Digital printing is additionally functional.

By utilizing different materials and formats, businesses can produce one-of-a-kind advertising and marketing materials that stand out from their competitors and attract focus from their target audience. Digital printing also supplies consistency. With typical printing approaches, there is frequently variation between prints due to distinctions in ink protection, stress, and various other aspects.

This uniformity can assist construct client trust and integrity, showing that business is dedicated to providing top quality materials. Uniformity is specifically essential for businesses that wish to construct customer depend on and trustworthiness. By making certain that every print corresponds, services can show that they are devoted to supplying top notch materials and focusing on the details.

Little Known Facts About Digital Printing.

Furthermore, digital printing produces much less waste since it can publish on demand and in smaller amounts, decreasing the demand for excess supply and products. Digital printing additionally makes use of much less power compared to conventional printing approaches. Digital printers do not call for as much energy to operate, as they do not require to warm up as much or use as much power to run.

Some Of Digital Printing

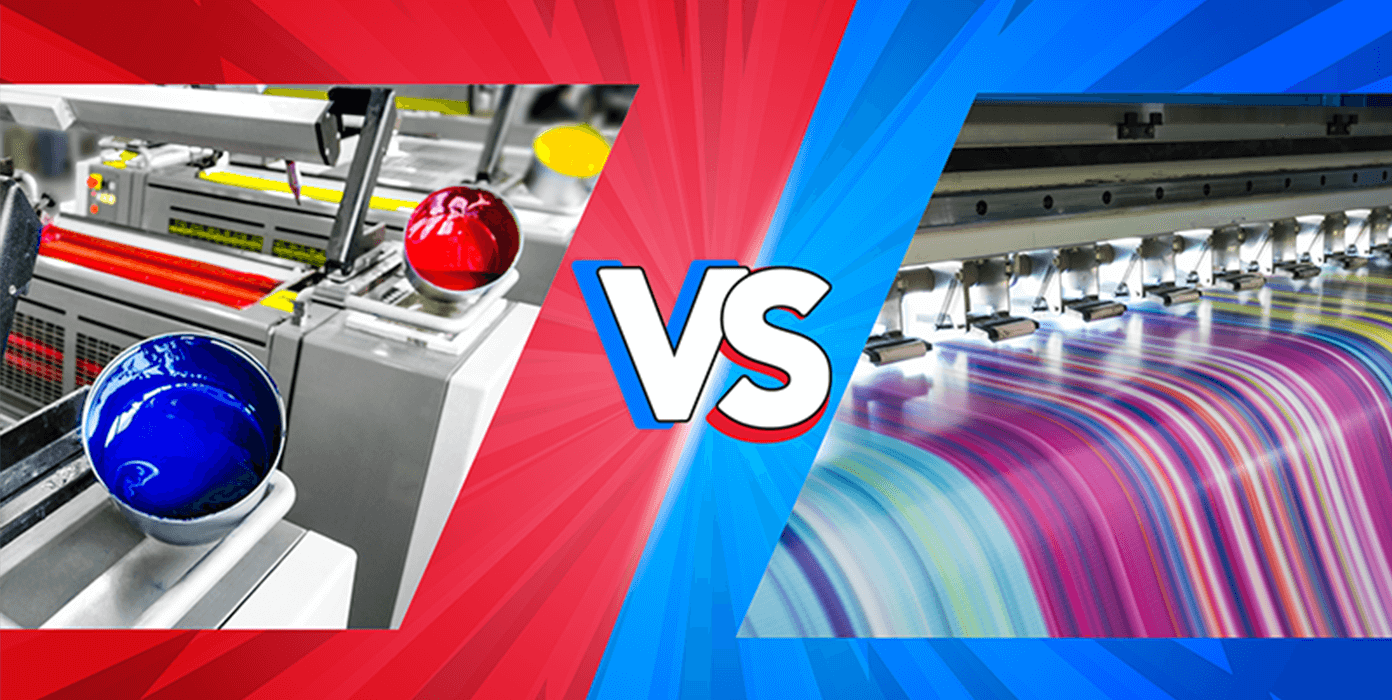

Offset printing needs a plate for every shade printed. Conventional balanced out printing is a print method that utilizes aluminum plates to transfer ink onto a rubber sheet (usually referred to as a "covering"). The photo is after that rolled onto the printing surface. This printing approach is taken into consideration "offset" due to the fact that the ink is not moved to the paper straight.

The 10-Minute Rule for Digital Printing

Balanced out printing permits for a large array of print products to be used during manufacturing. The top notch images generated through balanced out printing make it the favored approach, particularly amongst this visuals designers, when seeking the biggest shade reproduction, information, and professional-looking prints.

For electronic inkjet printing, ink is transferred straight onto the surface area. Instead than depending on aluminum plates and rubber coverings to transfer a picture, digital printing utilizes fluid ink during production.

Digital Printing Can Be Fun For Everyone

Since balanced out printing can blend custom shade inks for each job, it will naturally get the colors spot-on. Count on countered printing for tidy, unique kinds and photos without touches or places.

It sets you back a whole lot to begin a balanced out task. You need to spend money into producing the plates, which requires time. Nevertheless, as soon as you have actually invested it, all of the products are all set to go, and you'll invest much less on huge countered work than an electronic print, which has to do with the same per piece despite just how large the task obtains.

Each print is identical. You risk fewer weird variations caused by imbalances in water and ink. Digital printing is much less pricey for low-volume work. The rate per device goes down for digital printing, so at some time, they crisscross. Transforming info within a solitary print task. Say you were publishing out postcards advertising a show.

Examine This Report on Digital Printing

While digital printing or inkjet printing is the learn the facts here now recommended selection in today times, there are engaging reasons to convert from offset to digital printing systems. Contact Kao Collins about color matching and custom formulations. When printing offset or digitally, vital decisions and procedures are involved in color matching. If it has a graphic overlay or consists of a label, it will certainly have colors.

Industrial inkjet printing supplies flexibility for printing on many various substratums. Digital printing is perfect for customers who do not require longer runs and warehousing products.

One advantage of electronic printing is selecting from a broad range of electronic substrates. With offset printing, substratums comprise, on average, 30% of the price of the job. With digital printing, the expense of the substrate in the total task is tiny. This permits more options than ever, which benefits online marketers and organizations.

All about Digital Printing

drop-on-demand is the 2nd printing technology to consider. Continuous inkjet systems need considerable upkeep, her latest blog even more driver training, and greater downtime. Devices prices in inkjet printing are far lower than countered printing as there are no plate-making, plates, and press expenses. Beyond the capital expenditure, the prepress devices and printing presses require very skilled operators in countered printing, which adds labor expenses.

Report this page